SB Cantilever Beam Load Cell for Belt Scale Systems

Short Description:

The SB belt scale cantilever beam load cell from Labirinth load cell manufacturers is made of stainless steel and features IP67 protection. Its weighing capacity ranges from 0.5 tons to 7.5 tons.

Features:

1. Capacities (t): 0.5 to 7.5

2. Hermetically sealed versions available

3. High comprehensive precision, high stability

4. High quality alloy steel with nickel plating

5. Alloy steel or Stainless steel material

6. Weighing accessories and modules available

Applications:

1. Floor scales, platform scales

2. Weighing of hoppers and tanks

3. vehicle-test line

4. other electronic weighing devices

Description:

Single-ended shear beam load cell is a type of load cell designed to measure weight or force in industrial applications. It is a rectangular or block load cell that is fixed to a structure or support at one end and a load is applied at the other end. Load cells are usually made of stainless steel or other high-strength materials to withstand heavy loads, and it can measure loads from a few kilograms to several tons. Inside the load cell, there are four strain gauges mounted in a Wheatstone bridge configuration. The strain gauges are bonded to the load cell body and positioned in such a way that they will withstand compression when a load is applied. When the load changes, the strain gauge changes its resistance, and this change is converted into an electrical signal proportional to the applied load.

The single ended shear beam is designed for low profile scale and process applications. SB shear beam capacities are from 500kg to 7.5t. One end of the shear beam contains the mounting holes while the opposite end is where the cell is loaded. The load cell should be mounted on a flat smooth surface with high strength hardened bolts. The larger shear beam cells have more than two mounting holes to accommodate extra bolts to keep the hardware from stretching under stress load. Shear beams may be constructed of tool steel or stainless steel for use in harsh environments.

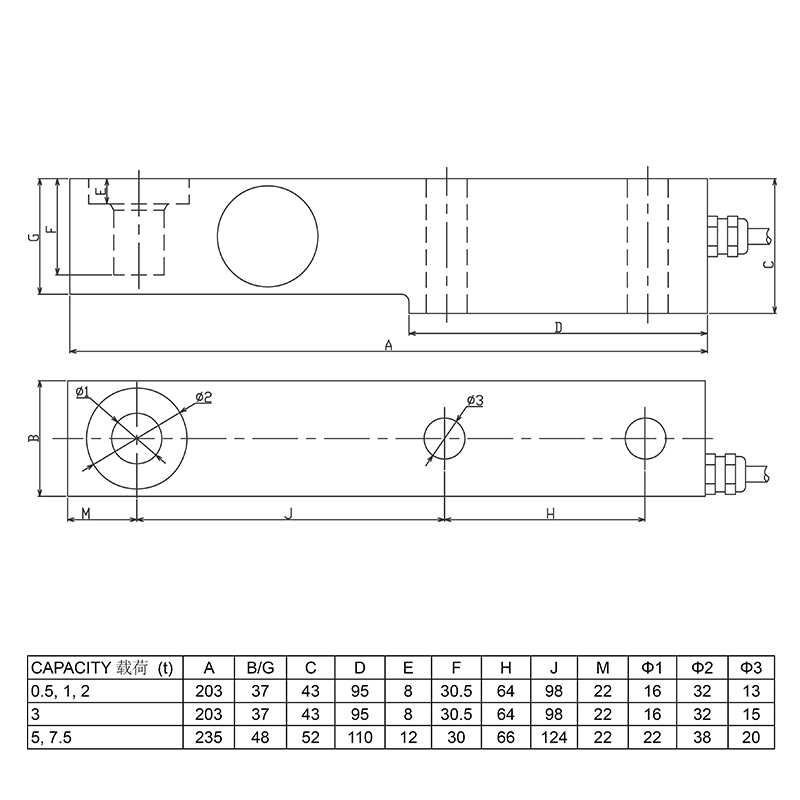

Dimensions:

Parameters:

| Specifications: | ||

| Rated Load | t | 0.5,1,2,3,5,7.5 |

| Rated Output | mV/V | 2.0±0.0050 |

| Zero Balance | %R.O. | ±1 |

| Com prehensive Error | %R.O. | ±0.02 |

| Non-linearity | %R.O. | ±0.02 |

| Hysteresis | %R.O. | ±0.02 |

| Repeatability | %R.O. | ±0.02 |

| Creep after 30 minutes | %R.O. | ±0.02 |

| Compensated Temp.Range | ℃ | -10~+40 |

| Operating Temp.Range | ℃ | -20~+70 |

| Temp.effect/10℃ on output | %R.O./10℃ | ±0.02 |

| Temp.effect/10℃ on zero | %R.O./10℃ | ±0.02 |

| Recommended Excitation Voltage | VDC | 46154 |

| Maximum Excitation Voltage | VDC | 15 |

| Input impedance | Ω | 380±10 |

| Output impedance | Ω | 350±5 |

| Insulation resistance | MΩ | =5000(50VDC) |

| Safe Overload | %R.C. | 50 |

| Ultimate Overload | %R.C. | 300 |

| Material | Alloy Steel | |

| Degree of protection | IP67 | |

| The length of the cable | m | 0.5-3t:4m 5t:5m 7.5t:6m |

| Tightening torque | N·m | 0.5-2t:98 N·m,3t:160N·m,5t:225N·m,7.5t:1255 N·m |

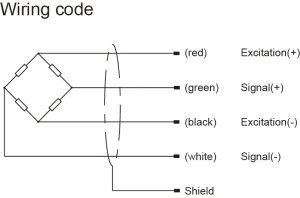

| Wiring code | Ex: | Red:+Black:- |

| Sig: | Green:+White:- |

Product specifications are subject to change without notice.